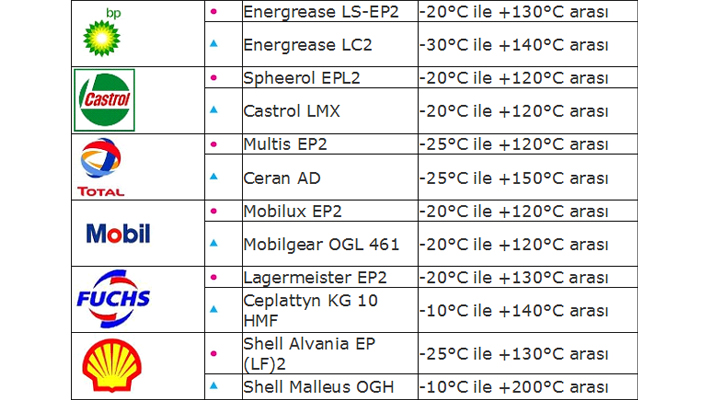

Another important factor affecting the service life of a Slewing Rings is lubrication. The Ball Bearing housings should be lubricated prior to operating after gear assembly. The housings should be re-lubricated after the first 25 hours work period and periodic lubrication should be carried out every 100 hours. Periodical lubrication is suggested every 50 hours for rolling bearings.

Lubrication should be carried out until all the oil on the dust felts in the grease nipple is removed and the same operation should be carried out for all the grease nipple holes. Since temperature will increase and corrosion will occur in case the housings are not well lubricated; it should not be forgotten that the working life of the gear will be short and operators should be warned.

The Slewing Rings should be selected according to the environment and the mixing of foreign material such as dust, sand, water, paint etc. should be avoided.

If your machine did not operate for a long time, the housings should be re-lubricated. In addition, the tightness of the bolts should be checked every 3 months and the dust felts should be checked every 6 months. Dust felts should be replaced with new ones if they are torn or they have lost their properties.